| Real Time Molten Metal Chemistry For The Galvanizing Industry

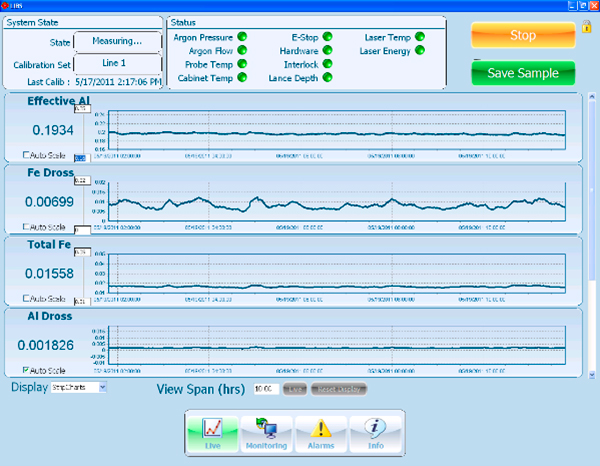

Laser Induced Breakdown Spectroscopy (LIBS) is a well know technology that provides instantaneous, non–contact, chemical analysis of almost any material and in all phases from solids to gas. Quantitative compositions are obtained from spectral analysis of the light emitted from a laser induced plasma plume. GALVALIBS combines LIBS with a patented molten metal sampling device to perform online, continuous, pot chemistry measurements. GalvaLIBS’ main features are:

• Measurement of effective Aluminum: 0.001-10%

• Measurement of effective Magnesium: 0.001-6%

• Measurement of effective Silicon: 0.001-3%

• Measurement of dissolved Iron: 0.001-1%

• Typical relative position (RSD) 1%

• Pot level measurement within ± 1 mm, unsensitive to drossing

• Estimation of pot cleanliness based on dross detection

• Completely autonomous (no human intervention)

• TCP/IP data interface to pulpit and plant network

• Extremely low consumable costs

• Remote service and troubleshooting capability via internet monitoring of embedded sensors

Advantages of the GALVALIBS over the laboratory

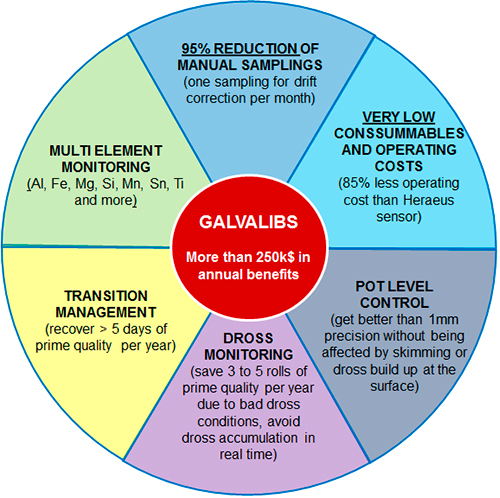

True Real Time

A real time reading will allow reacting immediately to changing conditions in the pot. As steel grade, line speed, and pot temperature can change within the time frame of two consecutive lab samples, the possibility of drifting out of pot chemical set points is always present. With real time measurements, the pot is always at its optimum and high quality parts can be processed at any time with confidence.

Pot cleanliness management

The GALVALIBS gives readout of the density of particles in suspension in the pot. This is revolutionary information that can easily be used to guaranty the quality of the coating in terms of dross effects at the surface. In situ industrial results have shown the dross readout is sensitive to line speed and pot temperature. A good integration of theses dynamics combined with especially design pot maneuvers could help predict the global pot cleanliness to either extend a Galvaneal sessions of a couple of weeks, shorten a Galvanize to Galvaneal transition or insure top quality product can be run more efficiently.

Real time pot cleanliness measurement is also very useful to detect severe iron contaminating events such as a bad steel grade, an out of spec surface cleaning or a surge in dross presence due to extensive cleaning of the pot area.

Increased accuracy

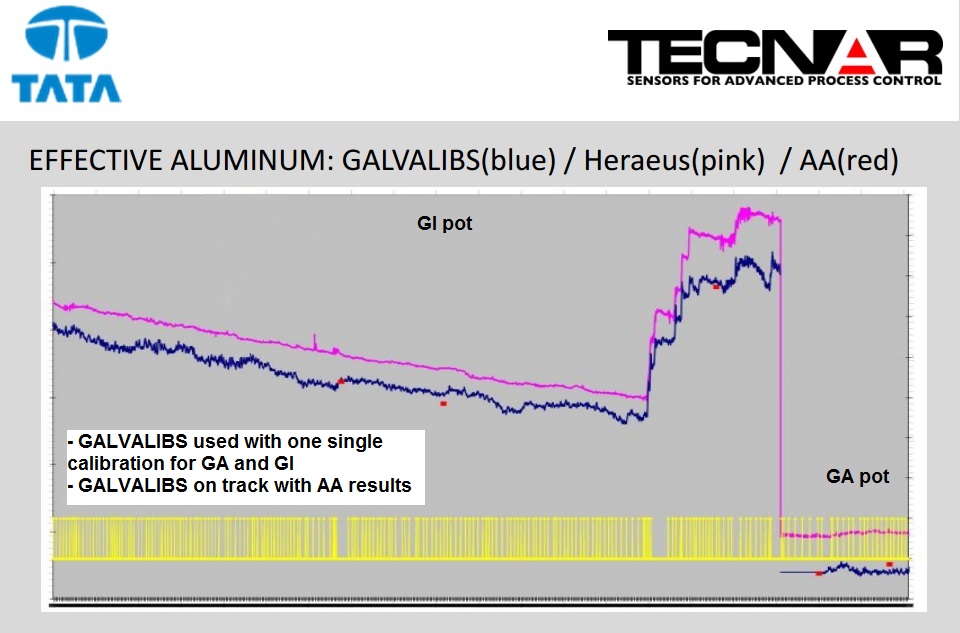

GALVALIBS does a direct measurement of the dissolved content. Unlike the laboratory practices or the other types of effective aluminum sensors for galvanization, the GALVALIBS does not include a mathematical calculus based on the temperature of the pot to evaluate the effective aluminum based on the total aluminum. The laboratory instruments and the disposable online sensors do projections from the total aluminum content on an empirical solubility curve for a given temperature. These methods add thermocouple errors with sampling errors and are responsible for many pot result misinterpretations.

Guarantied Reproducibility

The GALVALIBS, as an online continuous sensor, gives a reproducible result that cannot vary because of human sampling errors. Furthermore, with manual sampling, the consequence of a bad sample containing a large amount of dross for example, can extend to two sampling periods the time gap during which the plant operators are running blind.

Increased Safety

An online sensor will lower the direct access to the pot by human personal and therefore make the process safer.

Less laboratory expenses

A line that uses the GALVALIBS will only have to perform a few samples per week at the most just to verify the stability of the instrument as a recommended safety backup. For now, the new technology is not at the level of replacing the laboratory completely. Although Tecnar has the goal of putting in place a strategy to replace the laboratory in the future, the current strategy is to focus on reducing the laboratory expenses of about 80% and even more in cases where a company has many lines in a concentrated region that can share a single lab.

Top Top

|

|